Feature: Design Mind

The Meinig School’s creative, collaborative and applied approach to design.

by Syl Kacapyr

A small group of students frantically struggles to fashion together pipe cleaners and manila folders with string and paper clips. A student attaches a sock to the creation and attempts to slide it over her foot.

“Okay, time is up,” shouts James Antaki, the Susan K. McAdam Professor of Heart Assist Technology.

The students had been asked to quickly prototype a sock-assist device for people with mobility issues. It’s one of several creative ways Antaki introduces biomedical engineering design concepts in his BME 4080/4090 course.

“I then show students some commercially-available devices so they can juxtapose those devices to what they produced in class,” Antaki says. “Students learn the lessons of elegant simplicity and how to be resourceful. That gets their design juices going.”

It’s a simple exercise, but by the end of the two-semester course, students will have designed a wide assortment of inventive and original biomedical products such as an antibody-based diagnostic kit, devices to treat disease symptoms, and a cardiac monitoring system.

The Meinig School of Biomedical Engineering’s creative, collaborative and applied approach to design is infused throughout its curriculum, from first-year courses all the way through its master’s degree program. Students learn the essential elements of design thinking while learning about the human body and mechanisms of disease through biomedical engineering approaches.

“Think of it a little bit as working with training wheels,” says Marjolein van der Meulen, the James M. and Marsha McCormick Director of Biomedical Engineering, “students are getting bits of design practice along the way before riding without the training wheels their senior year.”

Biology Meets Design

Inside the walls of the Meinig School’s Weill Hall, biomedical engineers are designing vaccines, synthetic organs, machines that 3D print living tissue, and new strategies for treating diseases such as cancer and Alzheimer’s. Biomedical is an engineering discipline like none other, in which researchers must combine knowledge of technology and biology, and must design at the interface of living and non-living systems, among other challenges.

“The living system adapts to changes,” van der Meulen says, “and so when you design a valve for the human heart, for instance, the living tissue around the device is going to respond even if that material is accepted and is inert, things are going to grow around it or into it.”

Through a core set of course sequences, Meinig School students get acquainted with molecular, cellular, and physiological principles as multi-scale systems. And while students learn how molecular changes can affect tissue level-responses and how tissue can drive disease processes, that experience is embedded with hands-on design application.

“The idea is that they can work between these interfaces and that being creative is a key component to creating solutions in this space,” says Jonathan Butcher, professor of biomedical engineering and former director of undergraduate studies, who has played a key role in developing the school’s undergraduate curriculum since the launch in 2015.

By the end of their first semester, Meinig School undergraduates are already working on open-ended design challenges through courses like BME 1310: Introduction to Biomedical Engineering, in which a multi-week design challenge is one of the first opportunities students have to apply the design process to a problem of their choosing.

“Because it's very early in the design program, we really are focusing their efforts on creativity and the process of generating and evaluating ideas,” Butcher says.

While the designs usually tackle a variety of biomedical challenges, the spring 2021 semester provided a unique opportunity for students to design solutions for the COVID-19 pandemic, including designs for coronavirus tests, ventilators and social monitoring apps.

In BME 3030: Measurement and Instrumentation in Biomedical Engineering, students learn to produce high-quality measurements of physiological and biological variables by designing different approaches, sensors and systems with appropriate controls and calibrations.

Like BME 1310, BME 3030 emphasizes critical elements of the design process, such as how to develop a design history file – a detailed document recording research, modeling, design variations, testing and verification of a project, among other steps.

“It’s useful not only as an assessment tool of their creativity,” Butcher says, “but it helps students recognize the utility of that kind of portfolio element so they can consider that within the context of all the rest of their classes.”

Once students get to Antaki’s BME 4090 course, they are producing design history files that are hundreds of pages long, much like the documents they will be producing in their professional careers.

Improv Acting and Proof-of-Concept Prototyping

Lining the walls of Antaki’s Weill Hall office are books about classic and modern design theory, which are stacked next to books on topics such as creativity, acting and improvisation. It’s where he draws some of the inspiration for his capstone BME 4080 and 4090 courses, in which seniors receive instruction on the design process before embarking on an intensive design project to solve a real-world medical need.

“People think of design as using CAD software, 3D-printing something and then testing it, and students are very eager to do that on day one,” Antaki says. “But I don’t let them begin doing that until the spring semester. The entire first semester is learning principles of design, doing stakeholder discovery, pressure testing their ideas, and assembling a development plan.”

Along with lessons about affinity diagrams, how to interview physicians, intellectual property, and regulatory agencies, are improvisational exercises to get students to bring out the “artist within them,” Antaki says, “and to overcome their fears of being wrong.” These lessons include not getting too invested in an initial idea – a common trap engineers fall into, according to Antaki – and how to function in multidisciplinary teams.

In one exercise, students have 30 seconds to shout out as many ridiculous flavors of ice cream as possible. In another, students play the classic drama game “Yes, And” by entering a conversation in which every sentence starts with the words “Yes, and…,” with each statement becoming more exaggerated than the last.

“I want students to realize that they're full of ideas,” Antaki says, “and they should throw out lots and lots of ideas, and not fall in love with just one, because it might be a mistake. I want them to be prepared to pivot.”

To cap their undergraduate experience, students work in small groups to design and develop a proof-of-concept prototype for a medical product. For seniors, it’s the application of four years of biomedical and design knowledge. Projects in the spring 2021 semester included:

- Bugbyte—A blood test to diagnose bedbug bites with a complimentary app using image recognition.

- Stimuglove—A glove that provides in-home treatment for chemotherapy-induced peripheral neuropathy (CIPN) using customized scrambler therapy.

- Digestim—A digestive muscle stimulation waistband that reduces irritable bowel syndrome symptoms through targeted electrical stimulation and heat therapy.

- Sub Concussive Project—A headband for athletes to record and analyze cumulative head trauma that could lead to concussions.

“Working with this group was the highlight of my senior year in BME, and I cannot stress how valuable the entire design experience is,” says Rachel George ’21, project manager for the Stimuglove team, “from the way collective ideas converge in the initial brainstorming process to the final product that results months later. It was also incredibly rewarding to interact with real CIPN patients and see how much of an impact our design could have on their lives.”

[Read more about the Stimuglove design team]

Before graduating, students also have the option to design products through Cornell University DEBUT – a student project team and national biomedical design competition. In recent years, the team has developed a novel contraceptive, an allergy drug delivery device, a coronary bypass artery graft, and an ulcer prevention mattress system.

“I'm so impressed by these students, especially the way they stay so self-organized,” Antaki says. “They follow a rigorous process and it’s just really astounding.”

BME M.Eng.—Working With Physicians and Industry Professionals

For John Montani, M.Eng. ’21, his first time working with a physician and doing market research wasn’t on the job. It was as a graduate student in the Meinig School, where he designed new techniques for quantifying physiological and behavioral responses to pain.

“The fact that we are collaborating with an external company illustrates the value of this project,” says Montani, who collaborated with Hill-Rom, a medical technology company. “I value any opportunity I get to work on a project with such potential.”

The Meinig School’s one-year Master of Engineering degree requires graduate students to design biomedical devices within the bounds of health care economics, the needs of patients and physicians, and the medical device regulatory environment, among other considerations.

Students pursue many different pathways after obtaining their degree, but most are focused on landing an industry job. Montani hopes to pursue a career in the medtech industry.

The biomedical engineering M.Eng. program is led by Newton de Faria, professor of practice and M.Eng. program director, who spent two decades at NI Company—formerly National Instruments Corporation—before bringing his industry expertise to Cornell. He says enhancing design knowledge is just as important as the medical and industry connections students will make during their M.Eng. experience.

“We're trying to create this new generation of innovators that are not married to technology-driven innovation,” de Faria says, “They need to be concerned about value-based innovation, so they define a problem and then look for technologies that meet that need.”

To ensure their M.Eng. prototypes meet real-world needs, students choose to have their projects sponsored by a clinician, corporation, research lab or humanitarian organization. For example, students have worked with Guthrie Robert Packer Hospital on challenges in minimally invasive surgery, with Weill Cornell Medicine on neurological surgery, and with the College of Veterinary Medicine on peripheral nerve regeneration. And they have collaborated with companies like West Pharmaceutical and Johnson & Johnson on drug delivery technologies and medical devices.

The M.Eng. is a valuable opportunity for students to work directly with professionals, obtain new marketable skills, and in some cases, try out for a job. According to van der Meulen, it’s not uncommon for students to get hired by the companies sponsoring them.

“Newton has built some great partners for our students, and the industry experience that they’re getting is a really important part of our program,” van der Meulen says. “And at the same time, the industry and clinical partners really see the value in it.”

M.Eng. students also get an opportunity to interact with professionals during the graduate program’s annual Industry Engagement Day, in which over a dozen industry professionals attend a student poster session, career panel discussions, and a Shark Tank-style competition in which students pitch their projects to industry and faculty participants.

BME Design Complex

When James Bennett, M.Eng. ’21, was ready to prototype his design for an independent mobility device for toddlers, at his disposal were 3D printers, laser cutters, machining tools, wet labs and conference rooms. M.Eng. students gain access to these tools through the Meinig School’s BME Design Complex—a 2,600-square foot, state-of-the-art design facility inside Weill Hall, where students conceptualize and bring their ideas to life.

Inside the Design Complex, Bennett and a team of students built a small robotic wheelchair, with the goal of enabling environmental interaction and social behavior development in toddlers with mobility delays or impairments.

“I pursued a BME M.Eng. degree because I want to improve people’s quality of life through medical devices. I believe gaining in-depth knowledge of the lifecycle of a biomedical device, from concept to commercialization, and enhancing my ability to identify and address unmet health care needs is critical in achieving my goal.”

[Read more about Bennett’s infant mobility device]

The BME Design Complex was built by de Faria to emulate three industry environments: The office, where student teams can meet and brainstorm ideas; the laboratory, where students can fabricate parts of their design; and the design space, where students can prototype and test their designs.

“I want students to separate brainwork and ideation with the making process,” de Faria says. “It’s more the type of environment they will experience when they go off into industry.”

Inside the BME Design Complex, projects M.Eng. students worked on this year included a detection and response system for opioid overdose, a bioreactor for mature cardiomyocyte development, and augmented reality models for cancer mapping.

The Future of Biomedical Design

Only six years after its founding, the Meinig School’s undergraduate program has quickly gained notoriety as one of the top biomedical engineering programs in the country. Van der Meulen says the program will continue to break the mold of ‘textbooks first, design application last,’ by finding more ways to strategically integrate design thinking into its entire curriculum.

This push for concurrent biomedical and design theory education is one embraced by Antaki. As many of his students will attest, their undergraduate experience felt the most purposeful while applying biomedical concepts to design projects.

“Science is discovering the world as it is, and design is creating the world that never was,” says Antaki, paraphrasing the late engineer Theodore von Karman. “Students can learn about how cells migrate and how chemical pathways work, but design is where they truly become engineers.”

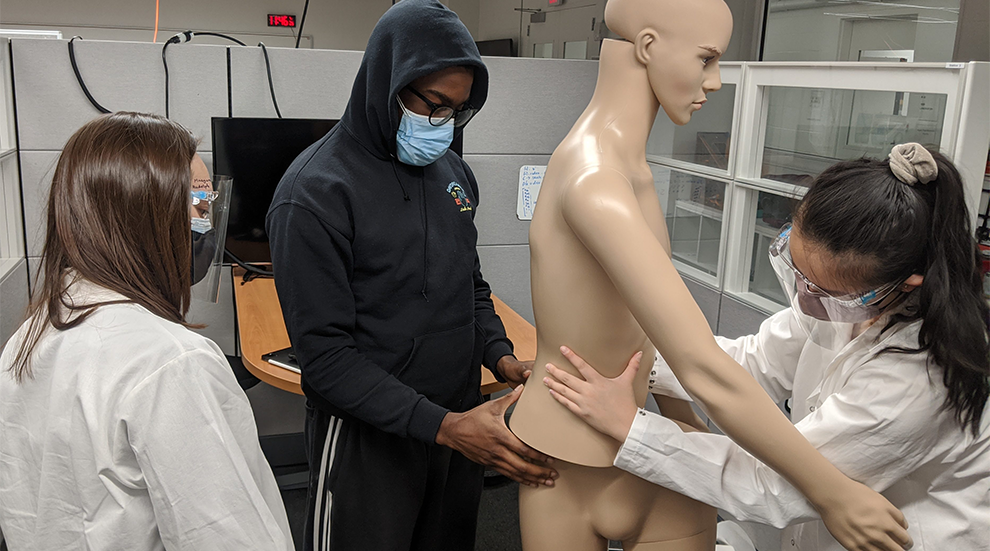

M.Eng. team Robotic Mobility Device

M.Eng. team Robotic Mobility Device meets at the Meinig School design studio for their sprint review, an exercise more effective and valuable when done in person. Students are required to follow a strict COVID-19 safety protocol—including masks, shields, lab coats, and distancing within their pods—that is closely monitored with a rf-id checking in and out system.

Design in the COVID-19 Era

As the COVID-19 pandemic was beginning to shut down laboratories across the country in the spring of 2020, Newton de Faria swung into action, helping many of the Meinig School’s research spaces avoid the same fate.

With the goal of keeping the BME Design Complex open, De Faria, professor of practice and M.Eng. program director, analyzed the facility’s airflow, added fans, and adjusted laboratory hood vents when necessary. He adapted spaces with separation barriers and created standard operating procedures that required students to follow safety and behavioral protocols. And an ID scanning and reservation system was developed to limit the facility’s population. Entry into the complex was akin to a ‘biosafety level 2’ lab.

“I had no problems with students following the protocols and procedures,” de Faria said. “We felt safe and it gave students the ability to remain productive.”

The protocols were so effective, several research laboratories throughout the Meinig School adopted them. In turn, some of those labs began conducting COVID-19 research.

“The pandemic has made the value of biomedical engineering incredibly apparent,” says Marjolein van der Meulen, the James M. and Marsha McCormick Director of Biomedical Engineering, pointing to biomedical engineers such as alumnus Robert Langer ’70, cofounder of vaccine producer Moderna.

Van der Meulen says Cornell University’s testing and health protocols also played a large role in keeping laboratories open, helping students retain one of the most valuable aspects of their educational experience.

“I participated in a virtual panel for a summer program, and students were asking me about applying to graduate schools without lab experience,” van der Meulen said. “We're really lucky because we had our students in the lab, graduates and undergraduates. It's been essential for us to have that campus-based presence.”

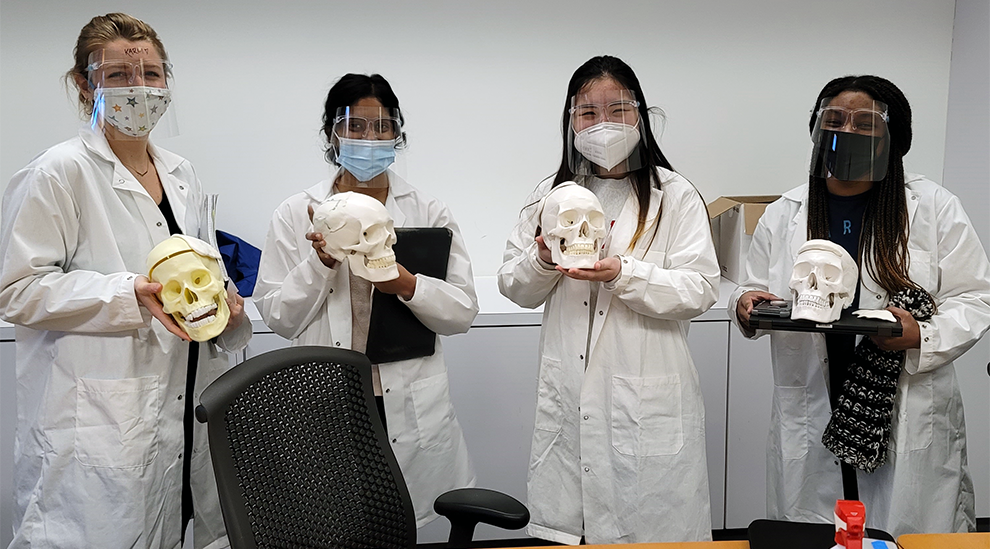

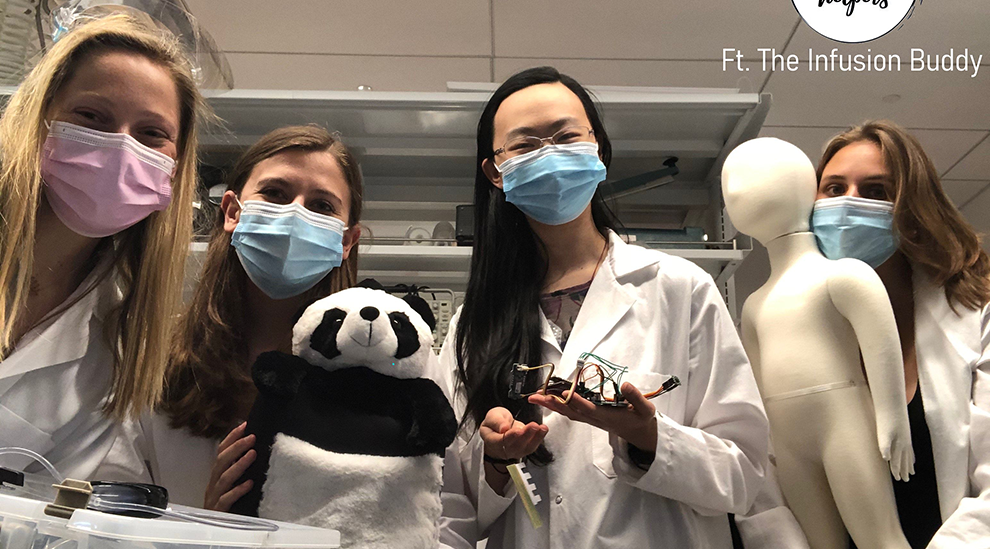

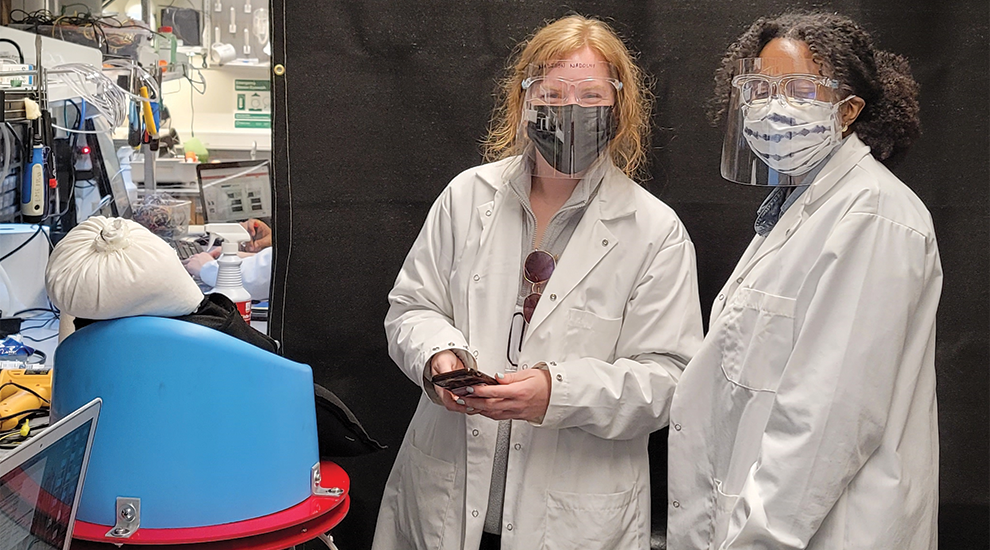

Meinig School leadership implemented many safety protocols early on that allowed students to keep design projects moving forward on campus and off. A few student teams working on projects on campus this past spring pictured here: